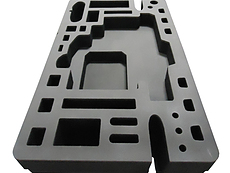

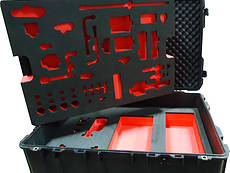

Foam Fabrication

Foam materials can be cut and shaped to serve any variety of needs. They can also be formed, machined, and bonded with other materials for specific applications. Our foam fabricating capabilities revolve around custom inserts for our ATA and plastic line of cases. We are available to do one off and large run on any foam project. We pride ourselves on our flexible scheduling and ability to meet most lead times that our competitors cannot.

Computer Controlled Routing (CNC)

Computer numerically controlled (CNC) routing is a process which uses computer guided drill and router bits for cutting and shaping of many materials. Utilizing CNC routing gives us the ability to design, prototype, and run the production of your project. We can work with substrates such as foams, plastics, and aluminum to machine custom precision parts in small quantities without the expense of tooling.

CNC routing is very useful when fabricating inserts for protective case and other specialty packaging applications as the routing heads can easily fabricate multiple cavity depths.

Water Jet Cutting

Water jet cutting uses a jet of water at high-velocity and pressure to cut materials. Water jet cutting provides precision cuts with no particulate issues. Water jet cutting is utilized on a variety of applications ranging from foam and plastic tool control trays to foam inserts for protective cases.

Laminating & Bonding

US Case has experience laminating multiple materials together including fabrics and foams. Laminating is used when there is a need to create composite materials for specific requirements whether it involves military, aerospace, electronics or if it is used to sharpen up a marketing kit and campaign. We offer a range of lamination capabilities including flame, heat and adhesive.

Flame lamination is utilized primarily when combining a foam to another material. The heat melts the surface of the foam, turning it into a tacky substance that essentially acts as an adhesive. That surface is then combined with another material, such as a fabric, and the two goods are then bonded together under pressure. Laminating with adhesives is one of the more traditional ways to make composite materials, and it remains an efficient and economical alternative for many applications.

Die Cutting

Die cutting is a fabrication process to cut and shape materials using various types of tooling and high tonnage presses. Our facilities have extensive die cutting capabilities including high speed, optically registered, kiss cutting, rotary and vacuum systems.

Foam Fabrication Image Gallery Click on an image to activate.